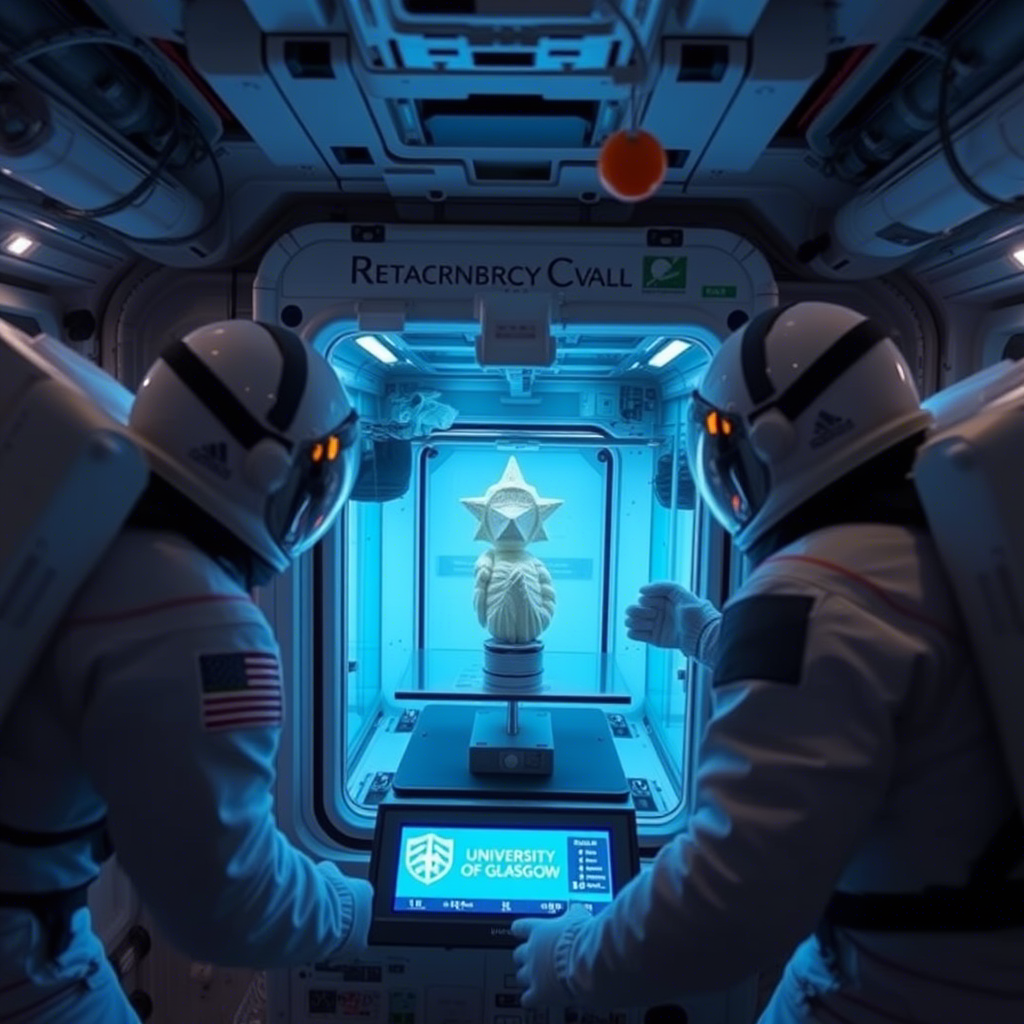

The future of space exploration just took a giant leap forward. Researchers at the University of Glasgow have developed a groundbreaking 3D printing system designed to operate during space flights, enabling on-demand manufacturing of tools, equipment, and even structural components in orbit. This innovation could solve one of the biggest hurdles in long-term space missions: the inability to carry or replace critical hardware mid-journey. Here’s why this tech could rewrite the rules of space travel.

Why Traditional Space Manufacturing Falls Short

Space missions today rely on pre-packed equipment launched from Earth, which is heavy, expensive, and inflexible. If a tool breaks or a part fails, astronauts have limited options – they either jury-rig a fix or wait months for a resupply. For missions to Mars or beyond, this isn’t sustainable.

How Glasgow’s 3D Printing Breakthrough Works

The University of Glasgow’s system uses a lightweight, modular 3D printer that can function in microgravity. Unlike Earth-based printers, it’s optimized for space conditions, using specialized polymers and metals that can be stored compactly and printed on demand. The printer can create complex parts layer by layer, from wrenches to replacement airlock components, without human intervention.

The Real Game-Changer: Sustainability and Adaptability

This tech isn’t just about convenience – it’s about survival. Imagine a Mars colony printing habitat parts using local regolith, or a spacecraft repairing its own hull during a deep-space mission. The system could also recycle materials from old equipment, reducing waste and dependency on Earth-bound supplies.

NASA and SpaceX Are Paying Attention

While the Glasgow team is still testing prototypes, agencies like NASA and companies like SpaceX have long sought in-space manufacturing solutions. NASA’s Artemis missions and SpaceX’s Starship ambitions require tech that supports sustained human presence beyond Earth. This printer could slot into those plans seamlessly, cutting costs and risks.

What’s Next? Challenges and Opportunities

The road to space-ready 3D printing isn’t without hurdles. Radiation, temperature extremes, and material limitations in space environments still pose challenges. But Glasgow’s team is already collaborating with ESA and private aerospace firms to refine the system. If successful, this could lead to:

- On-orbit satellite repairs, extending the lifespan of billion-dollar assets.

- Moon base construction using lunar materials.

- Emergency medical tools printed during crewed missions.

The Bigger Picture: A Stepping Stone for Interplanetary Civilization

This isn’t just about fixing a broken bolt on the ISS. It’s about enabling humanity to become a multiplanetary species. By decoupling exploration from Earth’s supply chain, 3D printing in space could make missions safer, longer, and more ambitious. As Dr. Lena Carter, lead researcher on the project, put it: “This isn’t just a printer – it’s a bridge to self-sufficiency in space.”

The University of Glasgow’s innovation is a glimpse into a future where space missions are no longer shackled by cargo limits or Murphy’s Law. While the tech is still in its infancy, its potential to transform space travel is staggering. One day, astronauts might look back and wonder how we ever explored the cosmos without it.